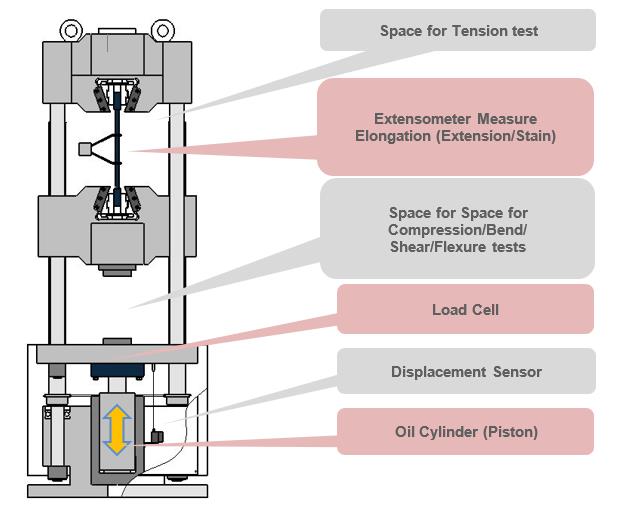

This servo-hydraulic Universal Testing Machine is ideal for high-capacity tension, compression, bend/flex, and shear testing. It is in accordance with the EN, ISO, ASTM, JIS, GB and many other standards. These frames feature dual spaces so users can quickly change between tension and compression testing without having to remove heavy fixtures.

Torontech is being increasingly recognized as a standard for accuracy, dependability and versatility in servo-hydraulic universal testing machines.

The TTDST3 is a desk top, triple target, turbo molecular vacuum pumped sputter coater, suitable for sputtering semiconductors, dielectrics, metals, and metal oxides. An evaporation source for thermal evaporation source can also be mounted on device for thermal evaporation process.

The TTDST3 is equipped with a large chamber and a water circulation cooling system for each cathodes which make it suitable for sputtering; a single large diameter specimen; and co-sputtering; a small diameter specimen.

According to state of the cathodes, TTDST3 is available in two models:

TTDST3 – A (Angled Cathodes):

The TTDST3-A is equipped with three angled cathodes with a common focal point. It can sputter from two or three targets simultaneously or independently to form alloys or multilayer deposition respectively.

TTDST3 – S (Straight Cathodes):

TTDST3-S with three straight cathodes is suitable for sputtering a single large specimen with a diameter up to 20 Cm or several small specimens.

The magnetron desk sputter coater is equipped with RF and DC power supplies It can sputter semiconductors, dielectrics and metal (oxidizing & noble) targets. The system is equipped with an easy-adjustable matching box, minimizing the reflected power in the RF sputtering. For increasing film adhesion to the substrate and to improve the film structures, a 300 V, DC bias voltage can be applied to the substrate.