TTPLD-T is a high vacuum thin film deposition system enables to deposit different materials by both Pulsed Laser Deposition and thermal evaporation technique. It can deposit complex materials and crystalline structures onto substrates with very little setup involved Pulsed Laser Deposition technique leads to efficient, none-thermal ablation and preserves the stoichiometry of the target materials. By applying this method, it could deposit materials such as nitrides, oxides, super lattices, polymers, composites.

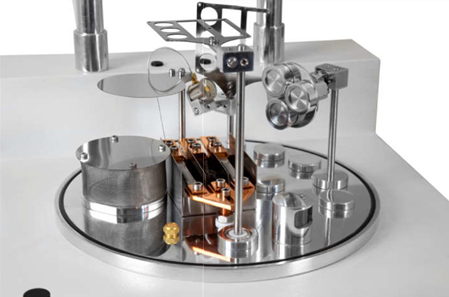

Thermal evaporation sources (Boat / Basket / Coil)

The PLD - T can be fitted with three independent heat resistance thermal evaporation sources. The good design of the evaporation source holder causes no contamination transfer from sources materials to other materials. The length of source holders can be adjusted in the range of 10 – 5 cm which meets the costumer requirement.

Target Manipulator

PLD - T is equipped with a multi-target manipulator which includes three 2 cm diameter. targets as standard.

All of our target manipulators are motorized and includes target rotation.

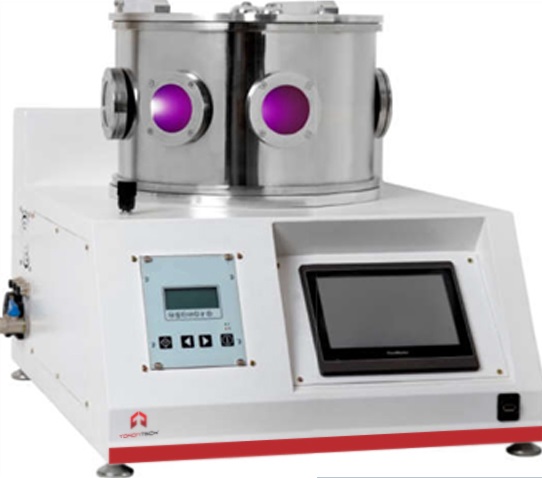

Touch screen control

The system is equipped with a 7'' colored touch screen and full automatic control and data input that can be operated by even inexperienced users. The vacuum, current and deposition information can be observed as digital data or curves on the touch screen. Information of the last 300 coatings can be saved in the history page.

High vacuum turbo pump 300 l/s.

Diaphragm backing pump.

Full range vacuum measuring gauge.

2.5 KW High current power supply.

Precision Mass Flow meter (MFC).

Able to record and plot coating parameters graphs.

Transfers the curves and deposition process data by USB port to PC.

Box Dimensions: 50 cm H x 60 cm W x 47 cm D.

Shipping weight: 48 kg