Density, a fundamental property that is often overlooked, holds the key to deeper understanding of the materials that shape our world. From the construction materials that build our homes to the pharmaceuticals that improve our health, the density of a solid material can reveal invaluable insights.

Accurately measuring the density of solid substances is a critical process, ensuring quality control, material identification, and process optimization across a wide range of industries. In this blog post, we will guide you through the importance of density testing and explore the various methods and tools available to efficiently analyze the density of your solid materials.

Understanding Density and Its Measurement

At the core of density testing lies a fundamental understanding of the concept of density itself. Density is a physical property that describes the mass of a substance per unit of volume. It can be expressed mathematically as:

Density = Mass (m) / Volume (V)

This simple formula underlies the importance of density measurement, as it allows us to quantify the compactness or “heaviness” of a material.

The most common units used to express density are grams per cubic centimeter (g/cm³) and kilograms per cubic meter (kg/m³). These units provide a clear and standardized way to compare the densities of different materials.

For example, the density of aluminum is around 2.7 g/cm³, while the density of gold is approximately 19.3 g/cm³. This vast difference in density is what gives these metals their distinct physical properties and applications.

Beyond metals, the spectrum of material densities is wide and fascinating. Solids can range from the low-density foams used in packaging to the high-density ceramics employed in advanced engineering. Liquids, such as water at 1 g/cm³, can also be characterized by their unique densities. Understanding these variations is crucial, as density is a key factor in areas like material selection, product design, and quality control.

Understanding the fundamental concept of density and how it is measured will better equip you to interpret density testing results and apply this knowledge to your industry and applications. Density data offers invaluable insights that can drive innovation, optimize processes, and ensure the consistent performance of your solid materials.

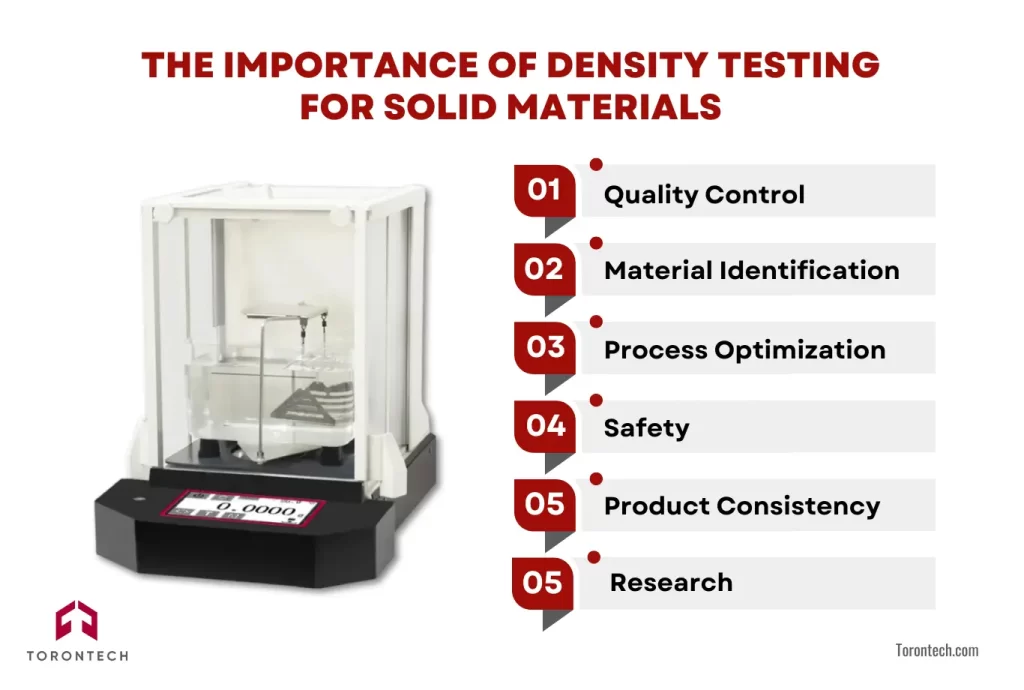

The Importance of Density Testing for Solid Materials

Density testing is an essential process in a variety of industries, providing valuable insights into the fundamental properties of solid materials. But why is density testing so important, and what are the practical applications of this measurement?

A. Quality Control

Accurately measuring the density of a solid material is a crucial component of quality control, ensuring that the materials used in manufacturing and production processes meet specific standards and specifications. For example, in the construction industry, density testing is used to ensure that concrete and other building materials have the required strength and stability to support the structure’s weight.

B. Material Identification

Density testing can also be used to identify the specific type of material being tested. For example, density testing can distinguish between different types of metals, plastics, and other materials, allowing for more accurate material identification and classification.

C. Process Optimization

Density testing can help optimize manufacturing processes by providing insights into the properties of materials. For example, in the pharmaceutical industry, density testing is used to ensure that the density of a powder or tablet is within the required range, ensuring that the drug is released into the body at the right rate and time.

D. Safety

Density testing can also be used to ensure the safety of materials, particularly in industries where the failure of materials could result in serious injury or damage. For example, density testing can be used to ensure that the density of a gas cylinder or pressure vessel is within the required range, reducing the risk of explosion or failure.

E. Product Consistency

Finally, density testing can help ensure the consistency of products, ensuring that the materials used in production processes are uniform and consistent. This is particularly important in industries where precise control over the properties of materials is essential for ensuring product quality and consistency.

F. Research

Density testing can also be a valuable tool for research and development, providing insights into the fundamental properties of new materials and recycling processes. For example, in the recycling industry, density testing can be used to analyze the properties of materials such as plastic, rubber, and wire and cable, enabling the development of more efficient and sustainable recycling processes.

Whether it’s for quality control, material identification, process optimization, safety, or product consistency, density testing is a powerful tool for ensuring the reliable and consistent performance of solid materials.

Methods and Tools for Testing the Density of Solid Materials

Testing the density of solid materials is a crucial process in various industries, as discussed in the previous chapters. But how do we actually measure density? This chapter delves into the various methods and tools used for density testing.

A. Common Density Testing Methods

1. Hydrostatic Weighing (Archimedes’ Principle)

This method relies on the principle of buoyancy. The material is submerged in a liquid (usually water), and the weight of the displaced liquid is measured. This weight directly corresponds to the volume of the material. Density is then calculated by dividing the material’s mass by its volume.

2. Pycnometry

This method uses a specialized container called a pycnometer. The material is placed in the pycnometer, and the volume is measured by adding a known volume of liquid (usually water) until the container is filled. The density is calculated based on the mass of the material and the volume of the liquid displaced.

3. Gas Displacement

This method utilizes a gas pycnometer. The material is placed in a sealed chamber, and a known volume of gas is introduced. The volume of gas displaced by the material is measured, and the density is calculated based on the material’s mass and the displaced gas volume.

B. Instrument for Density Testing

1. Density Meter (Density Tester)

These are electronic devices that utilize one or more of the methods described above to measure density. They offer a convenient and accurate way to determine density.

2. Density Gradient Columns

These are laboratory tools used to separate and analyze materials based on their density. They consist of layers of liquids with varying densities, and materials are placed in the column and allowed to settle based on their own density.

3. Density Balances (Hydrostatic Balances)

These are laboratory instruments designed to measure the weight of a material in air and water. The density is then calculated based on the difference in weight.

Introduce Torontech’s Range of Density Testers for Solid Materials

You’ve learned about the importance of density testing and the various methods used to measure it. Now, let’s delve into the practical world of density testing equipment. Torontech offers a comprehensive range of solid materials density testers, designed to meet the diverse needs of various industries.

A. The Challenges of Accurate Density Measurement

As you’ve seen, density is a crucial factor in various applications, from material identification to quality control in manufacturing. But achieving accurate density measurements can be challenging. Traditional methods often involve complex procedures, manual calculations, and potential for human error.

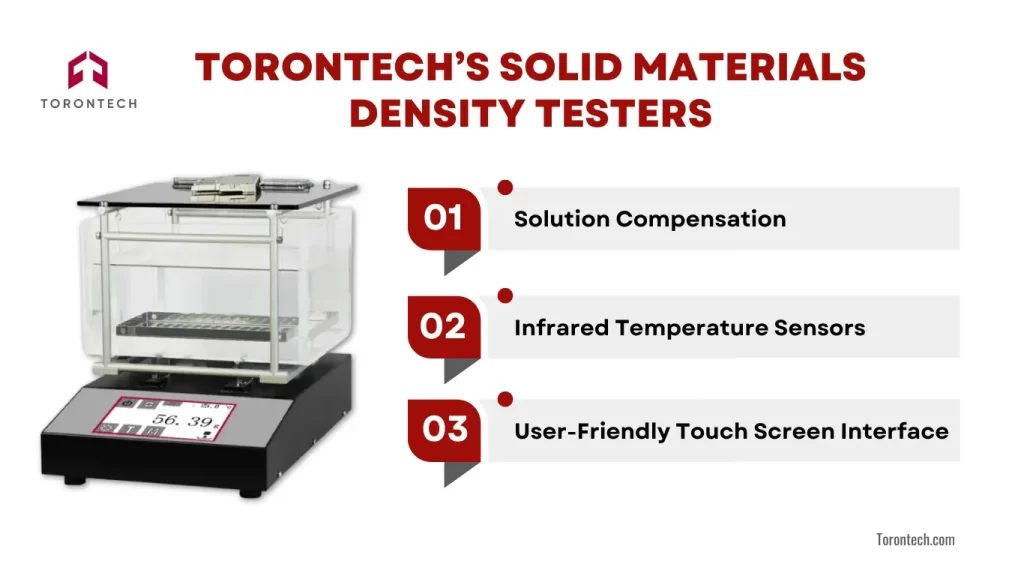

B. Torontech’s Solution: Precision and Efficiency

Torontech’s solid materials density testers are designed to overcome these challenges. Our advanced testers offer a combination of precision, efficiency, and user-friendliness, ensuring accurate and reliable density measurements for a wide range of materials.

Key Features of Torontech Density Testers:

1. Solution Compensation

Our testers automatically compensate for changes in water temperature, ensuring accurate density readings regardless of environmental conditions.

2. Infrared Temperature Sensors

These sensors automatically detect water temperature, eliminating the need for manual adjustments and reducing the risk of errors.

3. User-Friendly Touch Screen Interface

Our testers feature intuitive touch screen interfaces, making operation simple and straightforward, even for users with limited technical experience.

C. Our Range of Density Testers

Torontech offers a comprehensive range of density testers, each tailored to specific material types and applications. For the detail, please see in the below table.

| Model | Designed For | Sample Dimensions (LxWxH) mm | Maximum Weight Capacity (g) | Precision in Density (g/cm³) |

| TTD-1200E | Solid materials used in filming | 148 x 100 x 85 | 1200 | 0.001 |

| TTD-153E | Solid rubber materials | 148 x 100 x 85 | 150 | 0.0001 |

| TTD-214E | Solid film materials | 148 x 100 x 85 | 210 | 0.0001 |

| TTD-300DE | Aluminum samples (hydrogen content) | 148 x 100 x 85 | 300 | 0.001 |

| TTD-300E/600E | Solid rubber materials | 148 x 100 x 85 | 300 or 600 | 0.001 |

| TTD-300RE | Viscous materials | 148 x 100 x 85 | 300 | 0.001 |

| TTD-LE | Elastic solid materials | 210 x 170 x 120 | 1500, 2000, 3000, 6000 | 0.001 |

| TTD-SLE | Elastic solid materials | 290 x 255 x 160 | 2000, 3000, 6000 | 0.001 |

The latest models, Solid Materials Density Tester TTD-LE and TTD-SLE, feature unique weighing precision capabilities. The TTD-LE offers weighing precision of 0.01g for 1500g, 2000g, and 3000g capacities, and 0.1g for the 6000g capacity. Similarly, the TTD-SLE provides weighing precision of 0.01g for 2000g and 3000g capacities, and 0.1g for the 6000g capacity.

These models differ from other types in their exceptional accuracy for larger sample sizes, ensuring highly precise measurements for more demanding applications.

Conclusion

Throughout this explanation, we’ve highlighted the crucial role density testing plays in various industries, from quality control in manufacturing to research and development. Accurate density measurements are essential for material identification, process optimization, and ensuring the consistent performance of your products.

However, achieving reliable density measurements can be challenging. Traditional methods often involve complex procedures, manual calculations, and potential for human error. That’s where Torontech’s range of Solid Materials Density Testers comes in. Our advanced testers offer a combination of precision, efficiency, and user-friendliness, ensuring accurate and reliable density measurements for a wide range of materials.

We invite you to explore our comprehensive range of density testers for solid materials and discover how Torontech can help you optimize your density testing processes, ensure product quality, and drive innovation in your industry. Contact us today for more information, a consultation, or to find the perfect density tester to meet your specific needs.