Sputter Coaters / Vacuum Coating Systems - High-Vacuum, Double-Magnetron Target Sputter Coater/ Thermal Evaporator - DST2-TG

High-Vacuum, Double-Magnetron Target Sputter Coater/ Thermal Evaporator - DST2-TG

The High-Vacuum, Double-Magnetron Target Sputter Coater/ ThermalEvaporator-DST2-TG, or Double Target Turbo Pumped Sputter Coater and Thermal Evaporator, is a cutting-edge coating system that seamlessly merges thermal evaporation and sputter coating into a single compact desktop unit. This versatile technology offers remote system control through a convenient Wi-Fi connection, allowing users to manage operations effortlessly via a user-friendly touch screen or their PC.

Designed to operate within a high vacuum environment, this system is primed for depositing a wide array of materials, making it a go-to choice for diverse coating applications. The double magnetron target desk sputter coater offers the flexibility to switch seamlessly between evaporation and sputtering deposition, facilitating the creation of intricate multilayer coatings.

Experience the epitome of efficiency and precision with the DST2-TG—an all-in-one solution that revolutionizes coating processes within a glove box setting.

Glove box systems create a secure environment for delicate materials, preventing exposure to air, moisture, and unwanted interactions. The DST2-TG high-vacuum coating system integrated with a glove box ensures safe and clean handling of substrates before or after the deposition process, all within an inert gas atmosphere. This setup provides a precisely controlled chamber environment, enabling precise deposition of ultra-pure thin layers in high vacuum conditions.

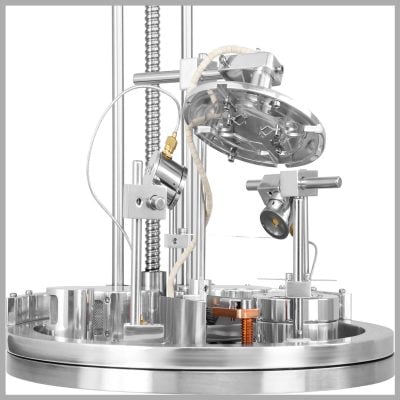

The DST2-TG, a state-of-the-art Magnetron Desk Sputter Coater, comes with a spacious chamber (300 mm diameter) and two 2” diameter water-cooled cathodes, making it ideal for extended deposition periods. This versatile system serves as a single platform for sputtering, carbon fiber deposition, and metal evaporation. Specifically designed for glove box use, the desk sputter coater can effectively sputter semiconductors, dielectrics, and metal targets. Users have the flexibility to install sputtering cathodes and thermal evaporation boats interchangeably or simultaneously, providing access to a total of three deposition sources. Moreover, carbon deposition is achievable through the utilization of carbon fiber, expanding the range of available deposition materials.

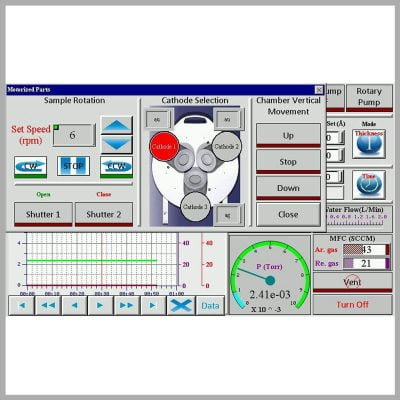

This highly precise vacuum coating system is designed to be semi/fully automated, featuring a user-friendly 7” colored touch-screen panel for controlling and adjusting the deposition process data. The intuitive software interface simplifies the operation. Users can also access the control panel window on their PC through a Wi-Fi connection. The system allows for monitoring vacuum levels and coating sequence information, which can be displayed as digital data or curves on the touch screen. Additionally, the last 300 coatings are saved and accessible in the system's history page.

Product: DST2-TG Touch Screen Vacuum Coater

The sputter coater and thermal evaporator for glove box applications can be enhanced with optional facilities, including: