GC for Analysis of Dissolved Gases in Transformer Oil (TOGA)

GC for Analysis of Dissolved Gases in Transformer Oil (TOGA) TT-3612

GC for Analysis of Dissolved Gases in Transformer Oil (TOGA) TT-3612 conforms to ASTM D3612 Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography.

It is used for measuring gases dissolved in electrical insulating oil with a viscosity of 20 cSt (100 SUS) or less at 40°C (104°F).

Oil and oil-immersed electrical insulation materials may decompose under thermal and electrical stresses, generating gaseous decomposition products of varying composition that dissolve in the oil. The nature and amount of these individual gases, once recovered and analyzed, can indicate the type and severity of the abnormality causing the gas generation. Monitoring the production of specific gases over time is also used to assess the condition of the electrical apparatus.

Background

When electrical and thermal loads are applied to transformers, the insulating oil and various components can decompose, producing byproducts that dissolve into the transformer oil as gaseous compounds. The analysis of these gases, called dissolved gas analysis (DGA), is a common procedure performed on insulating oil sampled from electrical transformers. DGA can indicate the health, longevity, and potential error states of transformers. Given the large and growing number of transformers in modern electrical infrastructure, testing labs often face the challenge of limited throughput for the numerous received samples. ASTM D3612 Method C specifies the use of automated headspace sampling of the transformer oil, which allows for higher throughput compared to other DGA sampling methods, such as vacuum extraction or the use of a stripper column (e.g., ASTM D3612 Methods A and B, respectively).

1. The TOGA uses an Ethernet communication interface, allowing it to easily form a local area network for long-distance data transmission, remote control, and remote diagnosis.

2. It has a powerful and comprehensive power-on self-diagnosis function, intuitive fault information display, power failure storage protection, and anti-power interference features.

3. It uses a special anti-pollution composite column technology for transformer oil, greatly improving the column's service life.

4. The instrument undergoes strict aging tests before leaving the factory, with parameters preset, so the user only needs to perform a simple start-up operation.

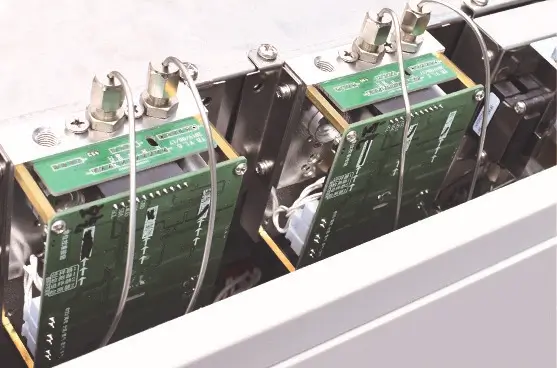

Small dead volume Injection system

High-precision gas flow control system

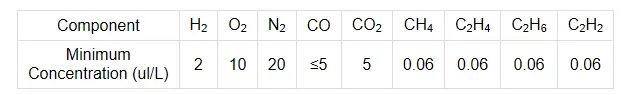

1. Injection volume: 1ml, with a minimum detected concentration of (ul/L)

DGA

2. Ambient requirements: 32°F to 104°F

3. Accuracy: ±0.1°C

4. Temperature control range: Ambient +5°C to 450°C

5. Analysis cycle: 7 minutes

6. Power: 1.9KW

7. Dimensions: 660 x 560 x 480 mm

High efficiency conversion device

FID(High sensitivity and low noise)

1. Real-time computer control and data processing

The TOGA system can expand the 10/100M Ethernet interface and connect to a local area network computer for remote data acquisition and management. This enhances device flexibility and promotes efficient laboratory applications.

The user-friendly software interface makes it easy to set parameters including temperature, range increase, events, and detector settings. Intuitive functions include FID automatic ignition, TCD switching bridge flow, temperature control activation and deactivation, range increase and decrease, and various timed events.

2. Unique gasification chamber and detector design

The innovative inlet design addresses injection bias, while the dual-column compensation feature mitigates baseline drift from program heating and reduces background noise, achieving lower detection limits.

The vaporization chamber design minimizes dead volume. Replacing injection pads, liners, polarizing poles, collecting poles, nozzles, and other accessories is straightforward. Main components like filling columns, capillary injectors, TCD, and FID detectors can be fully disassembled with just one wrench, simplifying maintenance.

3. High precision and stable temperature control system

The primary control circuit uses an advanced microprocessor, large-capacity FLASH, and EEPROM memory for reliable data preservation. The integrated circuit board design for measurement, control, and power supply enhances the TOGA’s anti-interference capability and reliability.

The microprocessor-based temperature control circuit ensures that the temperature accuracy in each heating zone reaches 0.1°C. The column chamber features a double overtemperature protection device, halting heating and reporting faults if temperatures exceed the set limit.

The intelligent double rear door technology maintains accurate temperature control when the column chamber temperature is near room temperature and allows for rapid cooling. The twenty-step programmed heating accommodates the analysis of complex samples with a wide range of boiling points.

4. Simple operation interface

The 7-inch LCD display supports capacitive touch, making it intuitive and easy to operate. It includes a self-diagnosis function and fault location display. The data power-off protection function ensures that operating data is preserved even after a power failure.

5. Protection

The system will stop heating if there is no carrier gas, protecting the column and thermal conductivity cell.

6. Auto ignition

The TOGA system allows for automatic ignition scheduling and includes hydrogen protection to extinguish the flame if needed.

Temperature control parameters

- Column Oven: Ambient +5°C to 450°C, Accuracy: ±0.1°C

- Injector: Ambient +5°C to 450°C, Accuracy: ±0.1°C

- Detector: Ambient +5°C to 450°C, Accuracy: ±0.1°C

- Maximum control: 7 paths temperature

Column Oven parameters

- Volume: 260 mm x 270 mm x 230 mm

- Programmed heating: 20 steps

- Programmed heating rate: 1 to 80°C/min (0.1°C increment)

- Retention time of each step: 0 to 655 minutes (1-minute increment)

- Automatic rear opening design for fast cooling, taking only 7 minutes to cool from 350°C to 50°C

- Powerful, low-noise fan for temperature uniformity

Detector

FID

- Unique and stable amplifier technology, with a specially treated signal amplification board for stable operation under harsh conditions

- Suitable for packed and capillary columns

- Operating temperature: 450°C

- Minimum detection limit: <5 pg C/s (n-Hexadecane)

- Linear dynamic range (LDR): 10^7 (±10%)

- Data acquisition frequency: 100Hz

- Automatic ignition: Auto hydrogen cut-off after flame extinguishment

TCD

- Suitable for packed and capillary columns

- Fast stabilization time, small dead volume, short equilibrium time

- Operating temperature: 400°C

- Data acquisition frequency: 100Hz

- Linear dynamic range (LDR): 10^5 (±10%)

- Minimum detection limit: <800 pg propane/mL (Helium)

Others

- Dimensions: 586 x 500 x 530 mm

- Weight: 46 kg

- Rated voltage: 220V ±50Hz, Power ≤2.5kW

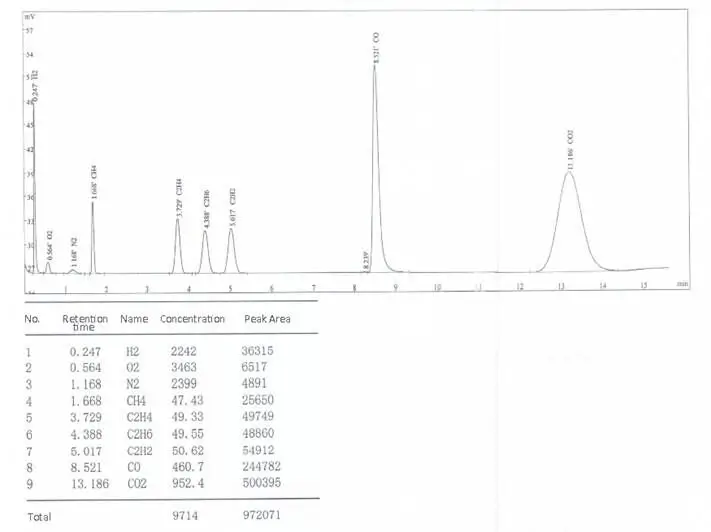

Chromatogram

Please Contact us for pricing, check availability, or ask for additional information about our GC for Analysis of Dissolved Gases in Transformer Oil (TOGA)