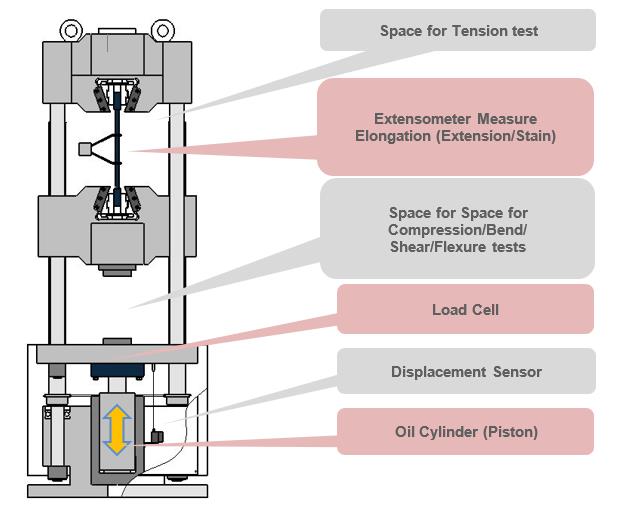

This servo-hydraulic Universal Testing Machine is ideal for high-capacity tension, compression, bend/flex, and shear testing. It is in accordance with the EN, ISO, ASTM, JIS, GB and many other standards. These frames feature dual spaces so users can quickly change between tension and compression testing without having to remove heavy fixtures.

Torontech is being increasingly recognized as a standard for accuracy, dependability and versatility in servo-hydraulic universal testing machines.

The TTDST1 series configured as a sputter coater suitable for Scanning Electron Microscope (SEM) sample preparation. A wide range of materials could be deposited by TTDST1 series such as gold (Au), platinum / palladium (Pt / Pd) alloy, silver (Ag), chromium (Cr), tungsten (W), iridium (Ir) and etc. This high vacuum coater offers high quality uniform films with fine grain sizes which are suitable for specimens that require high resolution and high-quality characterization such as FE-SEM, EDS/WDS, TEM, and EBSD

Nano & Microelectronic

Solar cell applications

Optical components coating

Thin film sensors