Are you looking for the perfect solution to achieve precise and high-quality coatings of noble metals? Look no further than the Desk Sputter Coater, a cutting-edge solution designed to revolutionize how you apply thin films of noble metals onto your specimens.

In the field of scientific research and analysis, noble metals like gold (Au), palladium (Pd), platinum (Pt), and gold/palladium (Au/Pd) play a crucial role. These metals possess unique properties that make them ideal for various applications, including scanning electron microscopy (SEM). However, applying uniform coatings of noble metals onto non-conductive or poorly conductive specimens can be challenging, often requiring advanced equipment and expertise.

That’s where the Desk Sputter Coater steps in. This exceptional coating system is meticulously engineered to meet the demands of researchers who require precise and uniform coatings of noble metals on their specimens.

With its compact design and versatile functionality, these instruments fit perfectly on any laboratory bench, saving valuable space while ensuring optimal performance. Gone are the days of relying on bulky and complex coating systems. The DSR1 brings simplicity and efficiency to the coating process, allowing researchers to focus on their core work without compromising on quality.

Understanding Noble Metal Coatings

Noble metals, such as gold, palladium, platinum, and gold/palladium alloys, hold immense value in scientific research and analysis. Their unique properties make them indispensable in various applications, including SEM analysis. However, achieving precise and uniform coatings of noble metals onto specimens can be a complex and demanding process.

Noble metal coatings play a vital role in enhancing the accuracy and reliability of SEM analysis. These coatings provide conductivity to non-conductive or poorly conductive specimens, enabling them to be properly imaged and analyzed under the electron beam. Moreover, noble metal coatings improve image resolution, reduce charging effects, and enhance contrast, allowing researchers to capture intricate details and gain deeper insights into their samples.

Applying noble metal coatings is not without its challenges. Factors such as achieving uniform thickness, controlling grain size, and ensuring adhesion to the specimen surface can pose significant hurdles. Uneven coatings or large grain sizes can compromise the accuracy and quality of SEM analysis, leading to misleading or inconclusive results. Therefore, researchers seek advanced techniques and equipment to overcome these challenges and achieve optimal coating performance.

Enter the Desk Sputter Coater, a game-changing solution designed to simplify and optimize the depositing of noble metal coatings. With its state-of-the-art technology and precision engineering, this instrument empowers researchers to overcome the limitations of traditional coating methods and unlock the full potential of noble metals in their analyses.

The Desk Sputter Coater ensures the deposition of uniform thin films with controlled thickness and fine-grain structures. This precision coating is essential for accurate SEM analysis, as it eliminates inconsistencies and provides a reliable foundation for imaging and elemental analysis. With this instrument, researchers or RnD in industries can expect consistent and reproducible results, enabling them to draw meaningful conclusions from their experiments.

Why Desk Sputter Coater is Important?

The Desk Sputter Coater is important to industries because it addresses several challenges and solves specific problems related to surface analysis, material characterization, and coating applications. Here are some of the key problems that this instrument can solve.

1. Surface Morphology Analysis

Industries often face the challenge of accurately analyzing the surface morphology of materials. The Desk Sputter Coater enables industries to prepare samples with a thin, conductive coating that reduces charging effects and enhances image quality during surface analysis techniques such as scanning electron microscopy (SEM).

By solving the charging problem, the instrument allows industries to obtain clearer and more accurate surface images, leading to better analysis and understanding of material structures.

2. Material Composition and Structure Characterization

Determining the composition and structure of materials is crucial for industries in various sectors. The Desk Sputter Coater allows industries to apply a coating of a known material, typically a noble metal, to samples. By solving the sample preparation challenge, the instrument facilitates the precise characterization of materials and aids in research, quality control, and product development.

3. Coating Uniformity and Control

Achieving uniform and controlled coatings on complex shapes or delicate samples can be challenging for industries. The Desk Sputter Coater gives industries precise control over coating parameters, including coating thickness, deposition time, and gas flow rates.

This level of control allows industries to achieve uniform and consistent coatings on a wide range of substrates, enhancing the performance, functionality, and aesthetics of products such as electronic components, optical devices, and biomedical implants.

The Desk Sputter Coater plays a vital role in industries by addressing these challenges and providing solutions. It enables accurate surface analysis, precise material characterization, controlled coating deposition, and enhanced product performance. Industries can benefit from improved research and development processes, higher quality control standards, and the ability to innovate and stay competitive in their respective markets.

Advantages of Desk Sputter Coater

The Desk Sputter Coater offers several advantages and benefits to industries. Here are some key advantages of this instrument:

1. Precise and Controlled Coating

The Desk Sputter Coater allows industries to achieve precise and controlled coatings on various materials and substrates. It offers adjustable parameters such as deposition time, coating thickness, and gas flow rates, enabling industries to tailor coatings according to their specific requirements.

This level of control ensures uniform and consistent coatings, improving product performance, reliability, and quality.

2. Versatile Applications

The Desk Sputter Coater finds applications in multiple industries, including materials science, electronics, optics, energy, automotive, and more.

Its versatility allows industries to enhance their research and development processes, improve product functionality, optimize surface properties, and advance their respective fields. The instrument caters to diverse industry demands, from thin-film deposition to surface analysis.

3. Enhanced Surface Analysis

In materials science, surface analysis is crucial for understanding the properties and behavior of different materials. The Desk Sputter Coater has played a pivotal role in enhancing surface analysis by providing uniform and controlled noble metal coatings on various materials.

Researchers have achieved improved imaging resolution, reduced charging effects, and enhanced contrast, enabling them to delve deeper into the surface characteristics and uncover valuable information about material composition and structure.

4. Customizable Coatings

The Desk Sputter Coater allows industries to customize coatings to meet specific requirements. By selecting appropriate coating materials and adjusting deposition parameters, industries can achieve desired characteristics such as adhesion, conductivity, corrosion resistance, and optical properties. Customizable coatings enable industries to optimize product performance, functionality, and aesthetics.

5. Time and Cost Efficiency

The Desk Sputter Coater offers time and cost efficiencies by streamlining the coating process. With its precise control and optimized coating parameters, industries can achieve desired coatings in a shorter timeframe, reducing production cycles and time-to-market. Additionally, the instrument’s energy-efficient design minimizes power consumption, saving costs over time.

6. Improved Product Performance

Coating critical components using the Desk Sputter Coater’s precise and controlled coatings enhances product performance in various industries. Improved conductivity, corrosion resistance, adhesion, and optical properties enhance products’ functionality, durability, and reliability such as electronic devices, sensors, optical components, and biomedical implants.

7. Reduction of Charging Effects

Charging effects can hinder accurate surface analysis, especially when analyzing non-conductive or poorly conductive samples. The Desk Sputter Coater solves this problem by applying a conductive coating to the sample, reducing or eliminating charging effects. This enables industries to obtain clear and detailed surface images, improving analysis and understanding of sample characteristics and facilitating more accurate measurements and evaluations.

8. Improved Adhesion and Durability

Industries often require coatings that exhibit strong adhesion to substrates and offer enhanced durability. The Desk Sputter Coater allows industries to deposit thin coatings of noble metals, which provide excellent adhesion and durability properties. These coatings can improve the performance and lifespan of various products, including electronic devices, sensors, coatings for automotive and aerospace applications, and corrosion-resistant layers.

These advantages empower industries to enhance their research and development capabilities, optimize production processes, and stay at the forefront of innovation and competitiveness.

What Industries Required This Instrument?

The Desk Sputter Coater finds applications in various industries and research fields. Here are some industries that often require this product.

1. Material Engineering

In material engineering, the Desk Sputter Coater has proven invaluable in optimizing the performance of various devices. Researchers have enhanced conductivity, reduced resistance, and improved overall device efficiency by coating critical components with noble metals. This instrument’s precise control over coating thickness and uniformity has enabled researchers to fine-tune the properties of materials used in electronic devices, sensors, and energy storage systems.

2. Electronics and Semiconductor

The electronics and semiconductor industry relies on the Desk Sputter Coater to coat critical components in electronic devices, sensors, and integrated circuits. The instrument’s precise control over coating thickness and uniformity enhances conductivity, reduces resistance, and improves overall device performance.

3. Nanotechnology and Nanoscience

The Desk Sputter Coater plays a vital role in the nanotechnology and nanoscience industry, enabling researchers to study and manipulate nanoscale materials and structures. Its precise coating capabilities facilitate high-resolution imaging and characterization of nanoparticles, nanowires, and other nanostructures.

4. Energy and Renewable Energy

The energy industry, including renewable energy sectors, benefits from the Desk Sputter Coater coating capabilities for optimizing the performance of energy storage systems, solar cells, and other energy-related devices. Coating critical components with noble metals enhances conductivity and improves energy efficiency.

5. Automotive and Aerospace

The automotive and aerospace industries utilize the instrument for coating components used in vehicle and aircraft manufacturing. The instrument’s ability to provide uniform and controlled coatings contributes to improved conductivity, corrosion resistance, and overall performance of these components.

6. Pharmaceutical and Biotechnology

The pharmaceutical and biotechnology industries can utilize the Desk Sputter Coater for coating samples and devices used in drug delivery systems, implants, and biomedical devices. Coating surfaces with noble metals can improve biocompatibility, drug release properties, and overall performance in these applications.

7. Optics and Photonics

The optics and photonics industry can utilize the instrument for coating optical components, lenses, mirrors, and waveguides. The instrument’s precise coating capabilities improve reflectivity, transmittance, and optical performance, enabling advancements in telecommunications, imaging, and laser technology.

8. Geological and Earth Sciences

The geological and earth sciences industries can employ the Desk Sputter Coater for coating geological samples, minerals, and rock specimens for SEM analysis. The instrument’s coatings enhance imaging resolution, reveal fine-scale features, and study geological processes and formations.

These industries and many others can benefit from the Desk Sputter Coater’s versatile coating capabilities, enabling them to enhance their research, product development, quality control, and analysis processes.

Introducing the Desk Sputter Coater- DSR1 from Torontech

Desk Sputter Coater- DSR1 is a revolutionary instrument that redefines the way researchers apply thin films of noble metals onto their specimens. With its advanced capabilities and user-friendly design, the DSR1 is poised to become your go-to solution for precision coating in SEM analysis.

This instrument is a compact and efficient coating system that brings simplicity and efficiency to depositing noble metal coatings. Designed with cutting-edge technology and meticulous attention to detail, this instrument empowers researchers to achieve optimal coating performance easily.

The Desk Sputter Coater – DSR1 offers enhanced productivity with its quick cycle time, allowing you to coat specimens swiftly and maximize your research efficiency. It ensures uniform coatings, eliminating the risk of uneven coatings that can compromise SEM analysis results and providing reliable and accurate data. The instrument also enables the deposition of fine-grain structures for high-resolution imaging and deeper insights into samples.

With a user-friendly design and intuitive touchscreen interface, the DSR1 offers seamless control and monitoring of the coating process. It incorporates a high-precision quartz crystal thickness monitor for accurate control over coating thickness and provides options for manual and automatic timed sputtering, offering flexibility to researchers.

The DSR1 also features GLAD sputtering capability for nanostructured coatings, plasma cleaning functionality for optimal coating performance, and easily interchangeable specimen stages for versatility.

Backed by warranty, CE conformity, and insurance coverage, the Desk Sputter Coater – DSR1 ensures your investment’s peace of mind and protection. Experience the advanced features and precise control of the DSR1, revolutionizing noble metal coatings and SEM analysis in research and analysis applications.

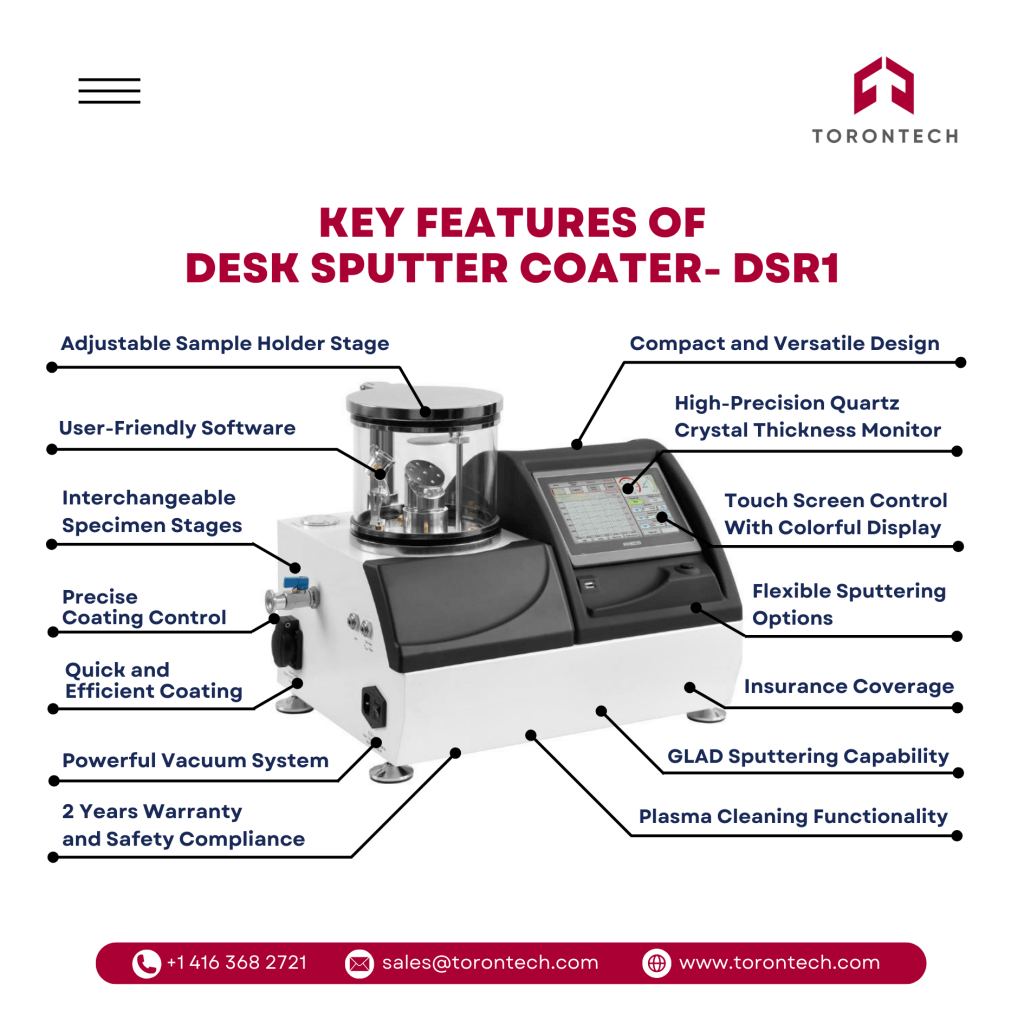

Key Feature and Functionally of Desk Sputter Coater- DSR1

Our instrument is a compact and user-friendly sputter coater designed for desktop use. It offers several key features that make it a versatile and efficient instrument for coating applications. Here are some of its key features.

1. Compact and Versatile Design

Features a compact design, making DSR1 perfect for desktop use in various laboratory and research settings. Its small footprint allows easy integration into existing workspaces without needing dedicated floor space. Additionally, its versatility enables the coating of various sizes and types of substrates, providing flexibility for different sample requirements.

2. Touch Screen Control With Colorful Display

DSR1 features a 7-inch color touchscreen interface, making it easy for users to control and operate the system. The touchscreen displays vacuum levels, current, and deposition information as digital data or curves, visually representing the coating process. The system also stores information on the last 300 coatings, allowing users to access the history page for reference.

3. Adjustable Sample Holder Stage

Our Sputter Coater provides flexible sample stage configurations to accommodate diverse user needs. The standard sample stage offers adjustable height, angle settings, and rotation capabilities, allowing easy customization. If you’re working with porous specimens and aiming for uniform coating, the rotary planetary sample stage is ideal, providing optimal coverage and consistency.

4. Precise Coating Control

With the DSR1, you have precise control over the coating parameters. Adjust the deposition time and coating thickness to achieve the desired coating characteristics. This flexibility allows for customization of coatings to meet specific requirements and ensures consistent and high-quality results. This instrument also provides precise control over the coating rate, enabling researchers to achieve finer grain structures and desired coating characteristics for their specific applications.

5. Quick and Efficient Coating

The DSR1 offers fast and efficient coating capabilities. It utilizes a magnetron sputtering technique, enabling rapid thin film deposition onto sample surfaces. This feature allows for quick turnaround times, improving productivity and reducing waiting times for sample coatings.

6. Powerful Vacuum System

The DSR1 is equipped with a two-stage direct-drive rotary vane pump with a 4m³/h capacity, ensuring efficient and reliable vacuum performance for the coating process.

7. High-Precision Quartz Crystal Thickness Monitor

With a built-in quartz crystal thickness monitor, the DSR1 allows for precise control over coating thickness, ensuring accurate and consistent results.

8. User-Friendly Software

The accompanying software is designed with ease of use and offers network update capability, allowing users to stay updated with the latest features and improvements.

9. Flexible Sputtering Options

The DSR1 offers manual and automatic timed sputtering options, allowing users to choose the most suitable method for their coating requirements.

10. GLAD Sputtering Capability

With GLAD (Grazing Angle Deposition) sputtering capability, the DSR1 enables the deposition of nanostructured coatings, opening up new possibilities for advanced research and applications.

11. Plasma Cleaning Functionality

The DSR1 features plasma cleaning functionality, which enhances coating performance by effectively removing contaminants from the specimen surface, ensuring optimal coating quality.

12. Interchangeable Specimen Stages

The DSR1 provides the flexibility of easily interchangeable specimen stages. The standard configuration includes a planetary rotation or rotation stage, allowing users to adapt to different sample sizes and types.

13. 2 Years of Warranty and Safety Compliance

The DSR1 is backed by a two-year warranty, providing peace of mind and reliable support. Additionally, it complies with CE conformity, meeting safety standards for user protection.

14. Insurance Coverage

The DSR1 comes with worldwide coverage for public and product liability insurance, ensuring protection in the event of property damage or personal injury caused by Vac Coat systems.

The Desk Sputter Coater – DSR1 combines these key features to offer researchers a comprehensive and efficient solution for their noble metal coating needs, with enhanced control, precision, and safety. Unlock new possibilities in your research, development, or manufacturing processes with this versatile and reliable sputter coater.

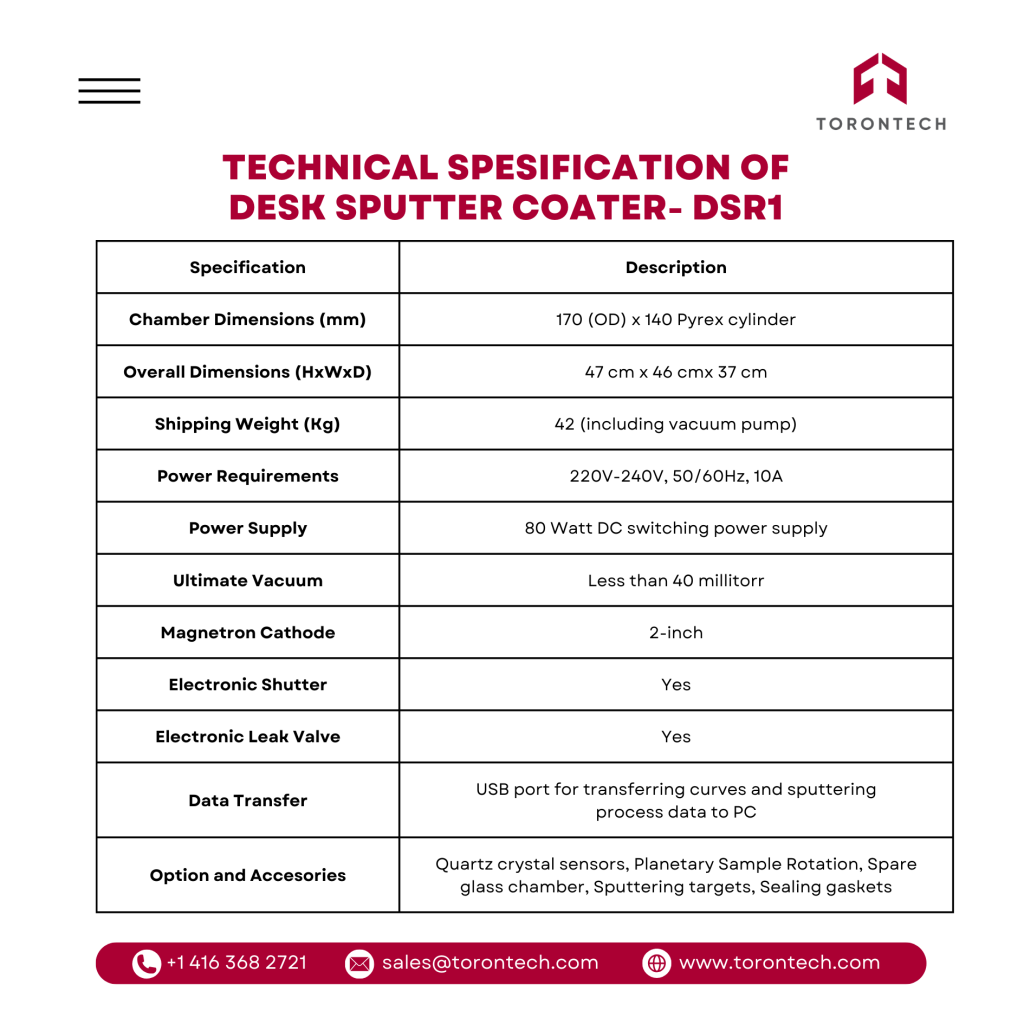

Technical Specification

These specifications provide detailed information about the product’s size, weight, power requirements, and key features.

Closing: Unlocking the Precision Coating Potential of Noble Metals with the Desk Sputter Coater

In the world of scientific research and electron microscopy, precision is paramount. The Desk Sputter Coater emerges as the ultimate solution for achieving precise and high-quality coatings of noble metals. It is a game-changer instrument, especially our DSR1.

With its advanced features and user-friendly design, it offers researchers the perfect solution for achieving precise and high-quality coatings of noble metals. From the intuitive touchscreen control and high-precision quartz crystal thickness monitor to the flexible sputtering options and interchangeable specimen stages, every aspect of the DSR1 is designed to empower researchers with unparalleled control and reliability in their coating processes.

Investing in the Desk Sputter Coater – DSR1 means unlocking a world of enhanced precision, efficiency, and reliability in your noble metal coating applications. This remarkable instrument allows researchers to delve deeper into their samples, make significant discoveries, and advance their scientific endeavors. Experience the difference and elevate your research with our Desk Sputter Coater, the ultimate solution for the precision coating of noble metals.

We understand that each project and application is unique. That’s why we offer personalized consultations to help you find the perfect coating solution with our Desk Sputter Coater. Our team of experts will work closely with you to assess your requirements, provide technical guidance, and tailor the coater’s settings to meet your specific needs.

Contact us today to schedule a consultation and unlock the precision coating potential of noble metals with the Desk Sputter Coater – DSR1.