Desk Sputter & Carbon Coater – DSCR-300

The large chamber Desk Sputter and Desk Sputter & Carbon Coater – DSCR-300, equipped with 3 or 4-inch water-cooled magnetron cathodes, serves as a compact coating system offering both sputtering and carbon coating capabilities. This system is well-suited for coating larger specimens, accommodating diameters of up to 12 cm when using a 3-inch magnetron or 15 cm with a 4-inch magnetron. Additionally, it can handle multiple smaller specimens with similar diameters. The water-cooled magnetrons are designed to extend sputtering time, making it ideal for depositing both thick and thin layers as required for various applications.

The Desk Sputter Coater model DSCR-300 offers versatile deposition capabilities on various substrates, making it suitable for thin film applications in fields like micro and nanoelectronics, as well as SEM sample preparation. It has the capability to sputter noble metals, including gold (Au), palladium (Pd), platinum (Pt), and gold/palladium (Au/Pd), onto non-conductive or poorly conductive specimens. Additionally, the DSCR-300 system is capable of applying carbon films.

Please note that for sputtering oxidizing metals, the installation of a turbomolecular pump is required and can be added to either the DSCT-300 or DSCT-170 system. The DSCR is a rotary pumped coater that can be configured for both DC sputtering and carbon fiber coating (thread) with interchangeable heads, all integrated into a single instrument.

Sputter & Carbon Coater Applications

Sample Stages

The large Desk Sputter and Carbon Coater offers flexibility in sample stage configurations, accommodating sizes of up to 15 cm, depending on the user's specific requirements. These sample stages are designed with rotatable functionality, adjustable height settings, and easy interchangeability for added convenience.

SEM Sample Preparation

In SEM (Scanning Electron Microscope) applications, it is often necessary to prepare non-conductive or poorly conductive specimens before conducting SEM microscopy. Standard methods for this sample preparation involve Sputtering Deposition and Carbon Evaporation. Our system offers full automation options, ensuring that even beginners can operate it with ease. Additionally, our user-friendly software provides graphical representations of deposition information, making it accessible and cost-effective.

Carbon Coating Head

The device is furnished with an interchangeable head designed for carbon coating purposes. Its unique capability to load three carbon fibers, each with a diameter of 0.8 mm, enables the deposition of carbon layers on large samples, particularly suitable for applications involving Energy Dispersive X-ray Spectroscopy (EDX).

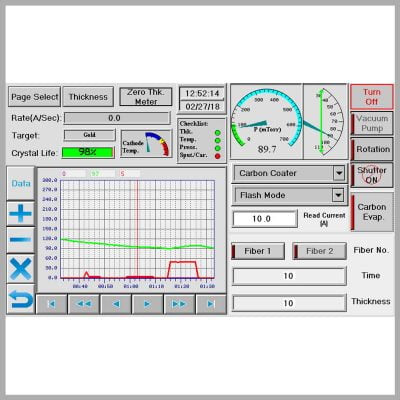

Touch Screen Control with Colorful Display

The DSCR-300 is furnished with a 7-inch color touchscreen that offers complete automatic control and data input capabilities, making it accessible even for inexperienced users. On the touchscreen, users can conveniently monitor vacuum levels, current readings, and deposition information, which can be displayed either as digital data or in graphical curve formats. Furthermore, the system has the capacity to store data related to the last 300 coatings, which can be easily accessed through the history page for reference.