Apparatus for Shear Stability of Lubricating Oils Containing Polymers

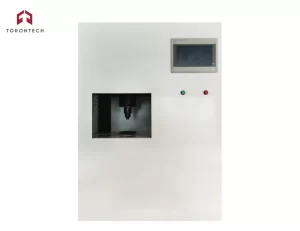

Apparatus for Shear Stability of Lubricating Oils Containing Polymers TT-51350-6

Apparatus for Shear Stability of Lubricating Oils Containing Polymers TT-51350-6 complies with DIN 51350-6 standards.

Apparatus for Shear Stability of Lubricating Oils Containing Polymers TT-51350-6 is utilized for testing lubricants in the Shell four-ball tester, specifically for determining the shear stability of lubricating oils containing polymers.

The tapered roller shearing system evaluates the viscosity shear stability of transmission lubricants. This equipment, a standard four-ball extrusion tester with a constant temperature device, includes components such as an embedded body, mandrel, tapered roller friction pair, tapered roller bearing, and temperature control instrument.

The tapered roller bearing tester (KRL) subjects the lubricating oil under test conditions similar to those in a gearbox, inducing mechanical shear stress. This stress leads to permanent viscosity loss and movement in the test lubricant before and after testing. The rate of viscosity decrease serves as an indicator of the lubricating oil's shear stability. This test method originated from the sixth part of the German standard DIN 51350, also referred to as KRL (Kugel Rollen Lager in German, abbreviated as KRL) or CEC L-45-99.

1. Dimensions: 640*380*895mm.

2. Motor speed: 1475±25RPM.

3. Temperature control mode: Utilizes an imported compressor.

4. Sample temperature: Maintained at 60±1°C.

5. Sample volume: 40±0.5ml.

6. Test load: 5000±200N.

7. Test period: 174000 cycles (approximately 19 hours and 40 minutes).

8. Power: 5.5KW.

9. Weight: 150kg.