AUXILIARY MACHINE FOR PLASTIC RECYCLING - Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF

Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF

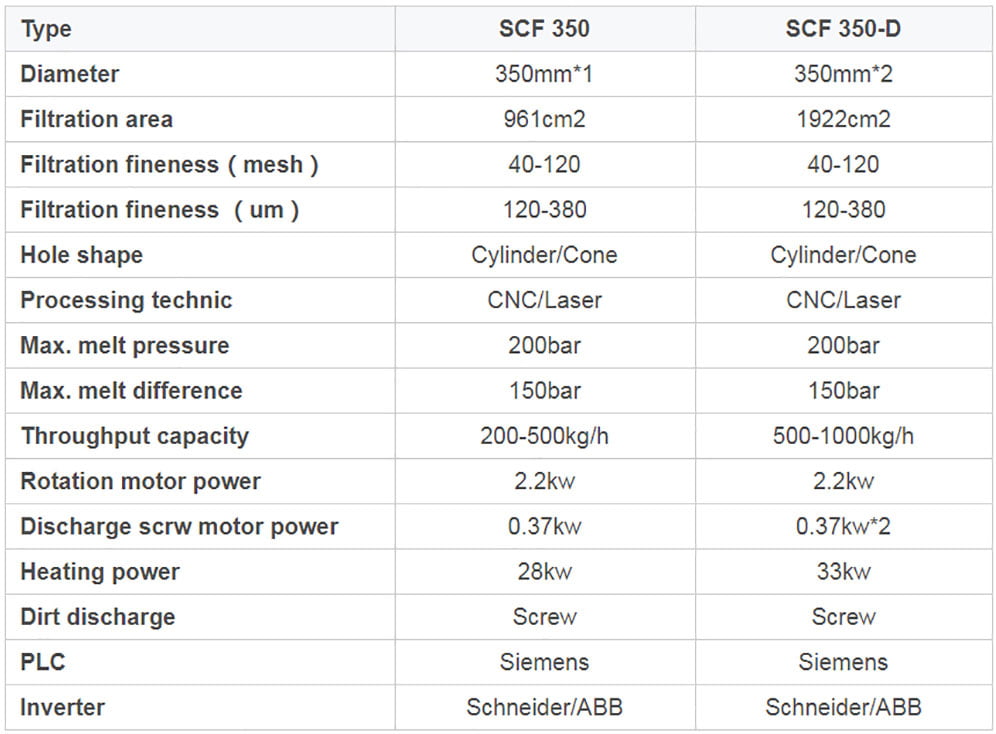

The Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF enables continuous recycling extrusion, ideal for highly contaminated materials re-pelletizing.

Unlike traditional screen changers needing frequent mesh changes, the Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF system offers continuous filtering, automatically removing contaminants from the steel screen plate. It features high automation and substantial production capacity, boosting recycled material rates and achieving a 1:1 slag discharge ratio (plastic content accompanying the discharge process).

Screen changer

The screen changer, whether manual or automatic, comprises one or multiple filters to eliminate foreign particles and impurities during material flow plasticization. The cleanliness of recycled materials and the technical quality of regenerated particles define filtration system standards. To address various melt filtration loads, conventional non-stop single-plate double-station or two-piston double-station screen-changing filtration systems are utilized, ensuring superior melt filtration performance.

SELF-CLEANING FILTRATION SYSTEM TT-SCF

The Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF self-cleaning filters features an effective accuracy of up to 120 meshes, enabling more efficient production of pelletizing lines exceeding one ton per hour output.

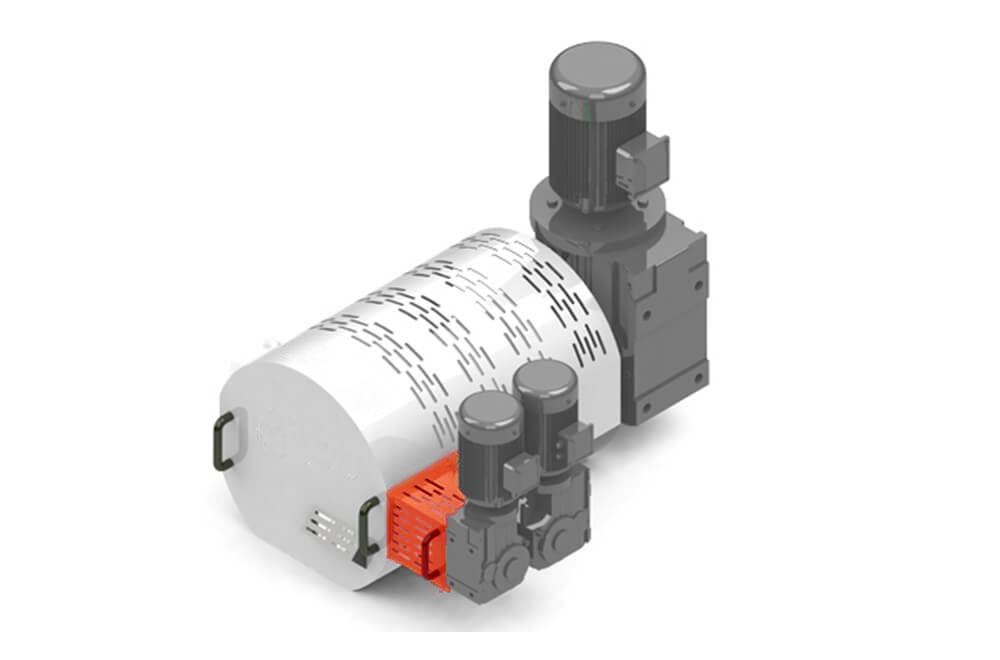

This filtration system comprises a hardened steel screen plate, rotating unit, hydraulic section, contaminant-removing blades, and a discharging screw.

FILTRATION SYSTEM TT-SCF

The Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF system efficiently manages and removes up to 5% of contaminants from the flowing melt, separating materials such as paper, wood, aluminum, unmelted plastic, rubbers, and more. Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF features an effective accuracy of up to 120 meshes, enabling more efficient production of pelletizing lines exceeding one ton per hour output.

This filtration system comprises a hardened steel screen plate, rotating unit, hydraulic section, contaminant-removing blades, and a discharging screw.

TYPICAL FEATURES TT-SCF

The Self Cleaning No Mesh Melt Filter For Plastic Recycling Pelletizing Machine TT-SCF system efficiently manages and removes up to 5% of contaminants from the flowing melt, separating materials such as paper, wood, aluminum, unmelted plastic, rubbers, and more. SCF self-cleaning filters feature an effective accuracy of up to 120 meshes, enabling more efficient production of pelletizing lines exceeding one ton per hour output.

This filtration system comprises a hardened steel screen plate, rotating unit, hydraulic section, contaminant-removing blades, and a discharging screw.