PET Plastic Recycling Machine Line With Polymerization System

The LSP Series is a PET Plastic Recycling Machine Line With Polymerization System featuring cutting-edge technology that utilizes Liquid State Polycondensation (LSP) to rapidly transform PET scrap or flakes into valuable products. This system offers versatility, capable of recycling bottles into new bottles, producing fibers, PET fiber, packaging strips, pellets, or films. It ensures full control over IV value and guarantees process stability.

PET Plastic Recycling Machine Line With Polymerization System Capable of handling diverse materials, this solution yields high-quality plastic granules while saving energy and reducing costs. It's an ideal choice for PET recycling factories aiming to enhance resource utilization and elevate resource quality. Reach out today to learn more about the LSP Series and its potential to transform your PET recycling process!

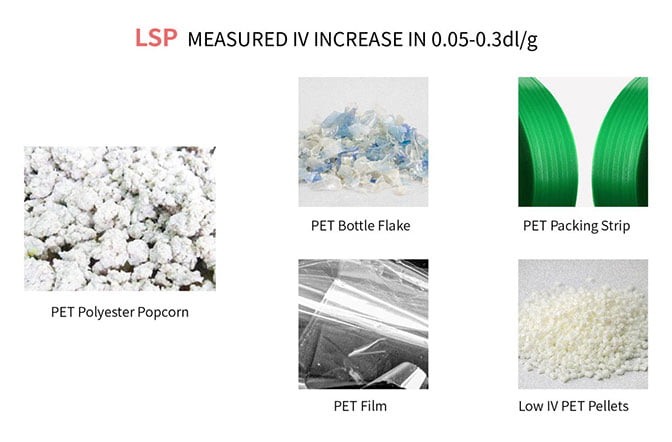

LSP (Liquid State Polycondensation) enhances the quality of recycled PET materials, including fiber, bottle flakes, film, and Low IV polymer. It facilitates the production of high-grade PET fiber, packaging strips, pellets, and film. LSP enables the recycling of bottles into new bottles, fibers into new fibers, ultimately improving resource utilization and the overall quality of recycled materials.

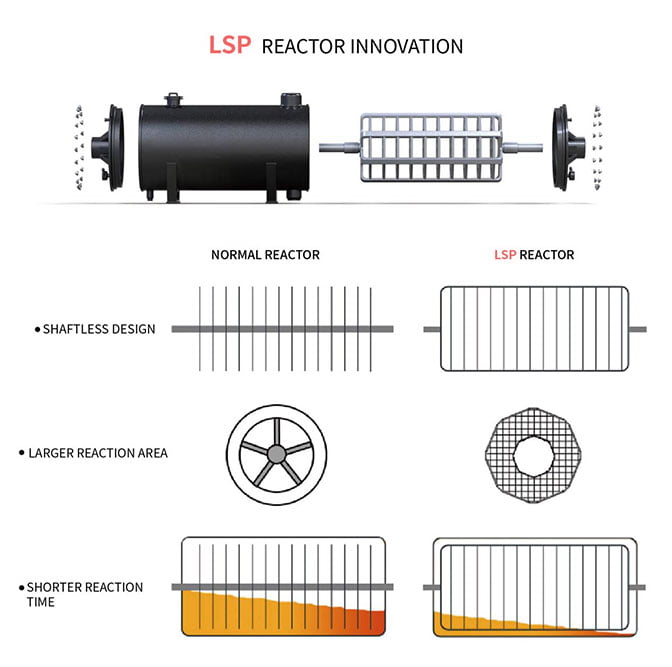

Innovation Structure

The reactor's innovative structural design expands the polymerization reaction area, enhancing the fluidity of PET melt and reducing reaction time.

Smart Control

Thanks to our new smart control system, operations and real-time monitoring are now more convenient than ever. This system allows for predictive maintenance and enhances production efficiency.

High Energy Efficiency

Frequency conversion equipment automatically adjusts operational frequency. The multi-level temperature control system minimizes heating energy consumption, reducing the overall operating costs of the system.

LSP Excellent IV Improvement Effect

Thanks to our effective homogenization feature, the reactor can blend various raw materials into a uniform melt.

LSP Achieve Higher Throughput

Our reactor's buffer enhances the overall controllability of the production system, boosting output and eliminating downtime during filter replacements.

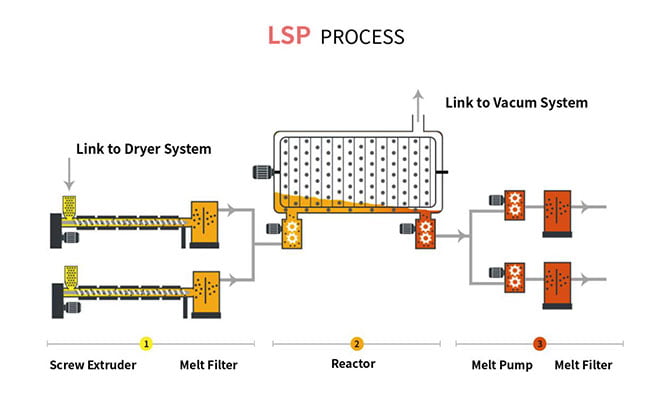

LSP Working Principle

LSP proves highly efficient compared to Solid State Polymerization (SSP) as it eliminates the need to cool down and reheat the polymer. Additionally, the reaction time in the melt phase is notably quicker than in the solid phase, further enhancing the economic advantages of the LSPLINE™ system.

Homogenization

Due to the complexity of recycled material sources and the difficulty in ensuring consistent components, the production process often encounters fluctuations in melt quality. To stabilize the IV, the reactor operates at a specific speed, ensuring thorough internal melt mixing.

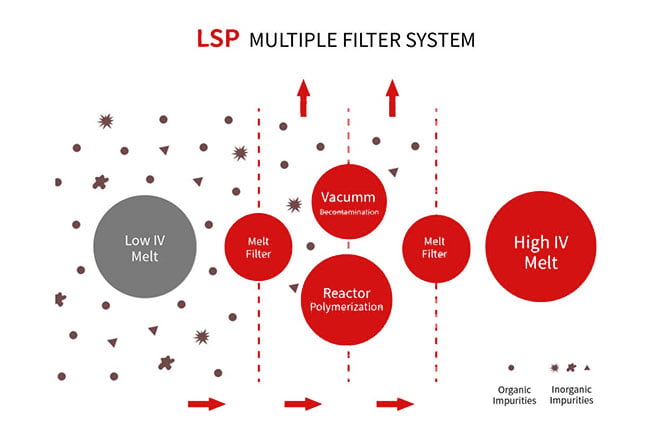

Remove Impurity

Because PET re-polymerization is carried out in a high vacuum state, the low molecular material contained in the raw material and the auxiliaries will be vaporized in high temperature.

Molecular Chain Growth

Despite the presence of a significant number of hydroxyl and carboxyl molecules in the raw materials, the catalytic system remains effective. Polymerization continues under specific temperature and vacuum conditions, leading to an increase in molecular chain length and IV.

After Extrusion

The initial melt filter following extrusion effectively removes inorganic impurities, aiding in the subsequent reaction.

During Reaction

In high vacuum conditions, the oligomers and decomposed gases are extracted from the melt and eliminated into the vacuum system.

After Reaction

The high-viscosity melt undergoes filtration through the final melt filter, capturing any remaining inorganic impurities within the melt.

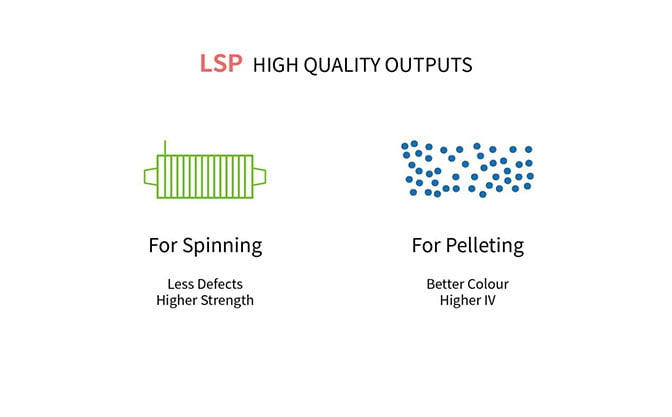

High Purity

Following multiple filtration and homogenization stages, the recycled polyester melt achieves enhanced purity and IV, resulting in a more uniform color in the end product.

High Strength

During the high-temperature and vacuum polymerization reaction, the molecular chains and IV consistently increase, thereby improving the strength of the resulting polyester product.

Non-shaft Design

The exclusive shaftless design ensures a smoother melt filming reaction, minimizing the risk of material buildup.

Larger Reaction Area

A larger reaction area enhances decontamination efficiency, boosts the effect of IV increase, and results in higher purity post-reaction.

Shorter Reaction Time

The innovative mesh design enables smoother melt flow, ensuring more stable liquid level control even at very low levels. This shortens the melt reaction time and enhances the color of the end product.